a good shed is hard to find

"itty bitty leashes" and other technical fragments of loom-centricity--with a crazy number of footnotes

When I hear the word shed I think about a roof—the angle of a shed roof to be precise—for it is an angle very much like the angle of the warp when you make a shed on a loom.

Alas, it turns out smallish outbuildings (other, perhaps, than weaving sheds)1, have nothing to do with the origin of the word.

The actual roots (in Middle English, Old Frisian, Old High German, Greek, Gothic, Old Saxon, Latin, Lithuanian….) are apparently to be found in myriad words that means to split, divide or separate (as a verb), or the part in the hair made by combing (as a noun). Of course these make much more sense than my invented association since separating is exactly what the shed on a loom does: create a temporary division of a warp into the strands that are up and the strands that are down—or forward and back as with the vertical warp below.

(btw: shed the building has a different origin entirely: from the Middle English shade, which was, originally, the barest sort of shelters)2

The division of the warp into ups and downs to make a shed can be done with a needle, fingers, or heddles—things that pull individual warp elements one way or the other.

And isn’t heddle a great word? Yes I know this post is supposed to be about weaving not etymology, but I find heddle to be slightly awkwardly delicious in my mouth. I remember muttering it under my breath in mid-January 1988 on my way home from my first weaving class, and then shouting it out loud as I burst through the door of the house I’d just moved into with my new boyfriend (now late husband):

“At last,” I cried, “I know what a heddle is!”

Dan was so startled he spilled his tea on the quizzes he was grading.

Not that I hadn’t been excited about the class before it began. Why else squeeze it into a schedule already overfull of lab-centric science classes? But my interest was more by way curiosity, of taking in the view on a branch of the yarn-centric path I was already treading with no expectation that the paths were merging irrevocably and that within a year Dan and I would be tucking our lives around the fringes of a 63 inch, 8 shaft Glimakra Countermarch loom3 —which is a a bit like choosing to build a post and beam barn in the middle of your living space.

At first my focus was domestic and sartorial—I wanted to make blankets, towels, yardage and maybe the odd rug—so the Glimakra (second hand from a local weaver), was a great fit. A year or so later when I was blindsided once again (this time by tapestry which I’d been sure I had no interest in it whatsoever), the Glimakra’s magnificent tension, huge shed and foot treadles were excellent for that too (many tapestry artists work only on such looms4). Once it became clear that weft faced imagery was where my future lay however, I decided to simplify. No need to squeeze my family into a half sized house when a vertical loom would take up so much less space—especially when a hard-to-find Shannock loom (also with treadles, amazing tension and a big shed) turned up for sale in the next town.5

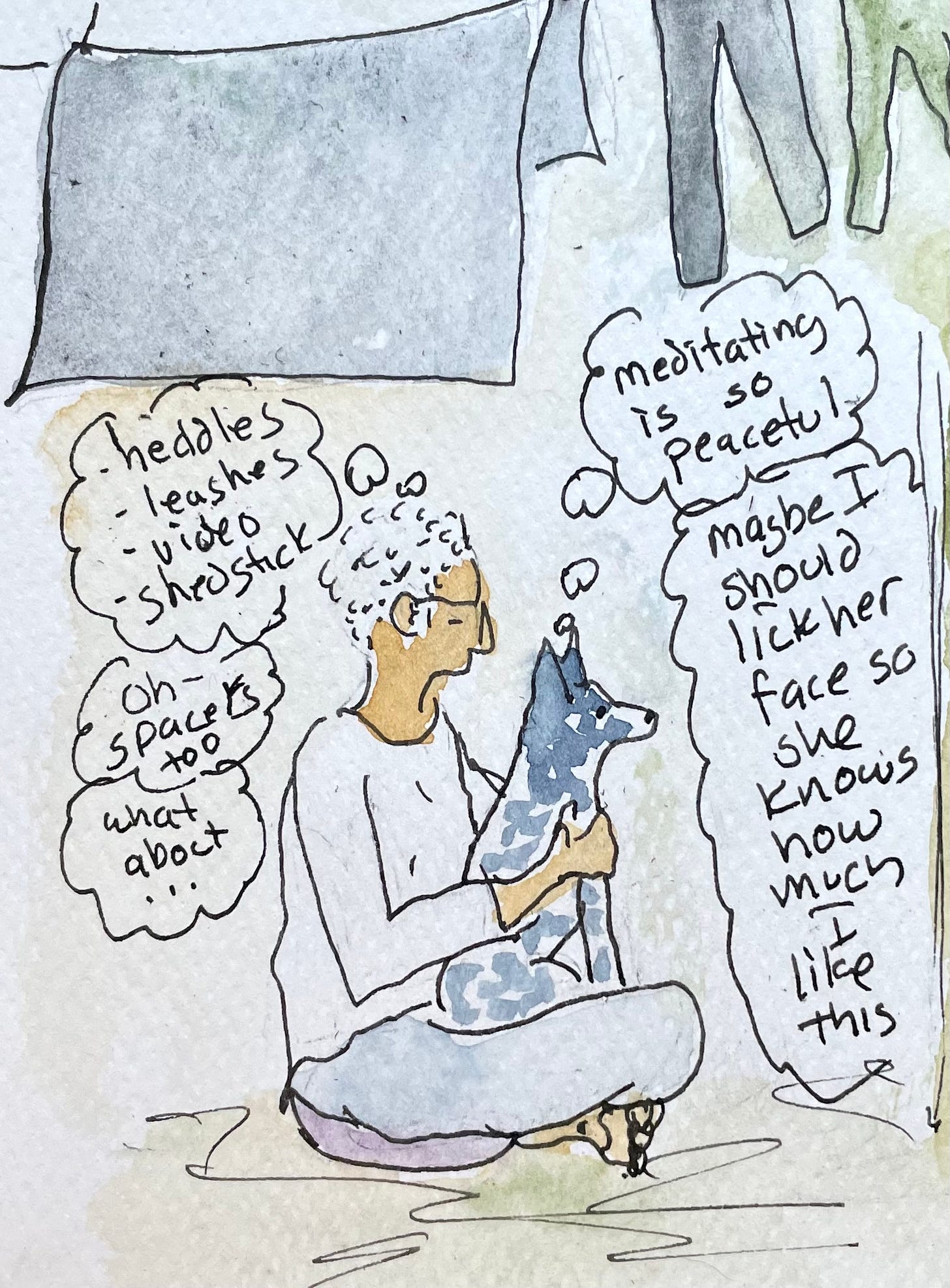

Since then and for various reasons,6 my looms have grown more elemental and the shedding mechanisms less mechanical until, as you know, I now work only on structures I’d not even have recognized as looms when I began.7 What is astonishing to me though, is that even as so much looks different, the things that really count haven’t changed a bit: each loom has had the ability to provide consistent, adjustable tension and the freedom to easily make a shed without my hands leaving the area of the tapestry I’m working on.

Treadles, of course, make this easy. With feet to do the work of changing sheds, hands are free to focus on the shape they are building. It’s also easy when there is no shedding mechanism at all: fingers of one hand scoop up warp threads one at a time and pull them forward while the other hand pops the weft through the gap— maximalist and minimalist approach with much in common.

Finger picking then (the latter technique), is pretty much how I weave now, with one (and sometimes two) additions that make it even easier. And it is those additions that this whole post is supposed to be about (etymology and my weaving history aside…oops. But I’ll stick with the point now).

The first mechanical addition is nothing more than a stick or dowel 1/4-1/2 inch in diameter woven across the warp. You can see the one I’m using right now in the photo above, and the essential triangular space known as the “open” or “stick” shed for obvious reasons.

To use it, I slide my hand up the warp until the open triangle is just wide enough for my fingers to slip into, scoop up the group of warp yarns I want to use (ideally no more than an inch worth), then pull those yarns toward me to open the shed. It’s a thing I can do entirely by feel.

And that’s it. One stick shed, one picked shed, and off I go. It’s intuitive, precise, and for me at any rate, incredibly efficient— especially for tiny or fiddly areas like letter forms. I don’t know that I can count the number of tapestries I’ve woven this way.

Not that you could have told me that twenty years ago when when I moved from the treadled Shannock to a metal pipe loom. Indeed, after over a decade of “treadling the boards,” it never would have occurred to me to forgo some kind of “proper” heddle system, so the warps on my first pipe looms all included leashes.

And leashes are terrific. Efficient and elegant, they are (and have been) a shedding mechanism of choice for tapestry ateliers for centuries.8

There is much I could probably say about them, but I think it’s better to show you these photos of weavings in progress, then turn you over to Tommye Scanlin’s excellent video describing how to use them.9 If you’re interested and haven’t tried them I totally recommend you go for it, at least once— if only for the romance. (I mean, don’t they look romantic draping there at the top of the tapestry? Or is that just me?)

There was never any real reason for me stop using leashes (efficient, elegant, romantic, mostly minimalist etc etc), except that one day I was so excited to begin weaving the tapestry at hand (whatever it was), that I started to finger pick the sheds. “Just a few passes,” I said to myself as I scooped my way across. “I’ll make the leashes tomorrow.” But tomorrow never came and I wove the entire tapestry (and every one after that), with a stick shed and finger picking and hardly noticed the lack.

Every one, that is, until 2017 when I taught myself to weave on a backstrap loom—and even then bringing the leashes back was kind of an accident.

The initial idea was to make long narrow word-centric tapestries, picking the sheds as I had been doing on a vertical loom, and it works perfectly. But in the process of messing around with backstrap looms I became inadvertently enamored with open balanced cloth as well (those sartorial leanings of decades ago?), and for that I needed a shedding device.10 Enter the string heddle.

At first I just made them when I was going to weave balanced cloth, but before long I found myself combining balanced and weft faced structures in one piece, and since the heddles—those “itty bitty leashes” as Ellen so aptly described them in last week’s comments—were right there, my hands automatically grabbed them to open the shed. And what wasn’t to love about that!

Indeed, it was so simple and pleasant that I began to add them to my “tapestry only” backstrap warps too. Why not?

It wasn’t until I was working on a wide backstrap tapestry with a strong stretchy wool warp however, that I brought the heddles to a vertical loom—again accidentally. The stretchiness of this particular warp yarn had not been an issue with narrower pieces, but it seemed I just hadn’t the strength to continually produce the necessary tension for a tapestry as wide as that one. What to do?

I considering just cutting it off, but instead built a pipe loom, wrapped the backstrap warp around it, fastened the beginning and end sticks together with luggage straps, and off I went as though I had intended to make a 3 selvedge continuous warp in the first place. The threaded rod on the loom provided the necessary tension, my back got a break, and I could focus on weaving. Relief all around. The heddles were an added an unexpected bonus.

“I’m going to do this more often.”

Unlike the long swooping leashes I’d used before, these heddles are low profile — only a few inches long—so the bar can stay close to the warp (vs hanging out in front the loom as you can see on Tommye’s video and some of hte photos above). They are also relatively quick to make with whatever materials are at hand (the red stuff is pearl cotton from a yard sale and I’ve already used it dozens of times).

There are probably all kinds of ways and reasons that long leashes make more sense (and if you know some do let me know in the comments cuz I always like learning things and having my mind changed), but I’ve been so content with these short ones these last few years that I can't think of a single reason to change back. They are relatively fast to make, don’t need much yarn/string, are super easy to use and keep my hands and fingers from getting as sore as they might when finger picking on a larger work. What’s not to love?

Not that I use them all the time. I am still happiest with finger picking and a shed stick for small fringeless pieces with fiddly bits. But for longish warps that are wider than, say, eight inches—especially those with large plain areas—the string heddle/itty bitty leashes are efficient, easy, and hard to beat.

So that’s the story of the red string.

As for the rest of the sticks:

There are two at the top because the piece of quarter round I’m using to hold the open shed is kinda short (just barely wider than the warp as you can see), so the super thin stick at the very top is backup — just in case the short one accidentally slides out of place.

The three sticks at the bottom are spacers —reserving a few inches of warp for edge finishing when the tapestry is off the loom. Some people weave in waste yarn at the beginning of a warp instead, but I like the sticks. A row of twining above them evens out the sett before I begin, and I can take the sticks out when I advanced the warp (as you can see, the ones I’m using here are wider than the loom so couldn’t advance them with the tapestry even if I wanted to).

Karen also asked last week if the backs of the big tapestries have all the weft ends woven in as I go,11 and the answer is yes! I don’t think I’ve left a tail on the back of a tapestry since I wove Improvisation on the Pirate Fairies in 1995.

And I think that is about it for today’s meandering technical narrative. As ever, Substack is telling me that the post is too long for email— and if you’ve read this far, thanks! I’ll be back next week with less tech and more Beryl.

And in the meantime, weave on (or play or knit or rest as you can).

Remember to comment with the button above rather than by hitting reply, for if you choose the latter I won’t see your lovely words.

And if you know anyone who might enjoy these meanderings, please do click the button below and see what they think!

The Glimakra Countermarch literally took up about half our usable living space..

You can see Mary Zicafoose and Rebecca Mezoff weaving on such looms in the line videos.

I wove on the Shannock for ten or so years. This link goes to a Rebecca Mezoff blog post where she talks about loom choice and shows a huge array of tapestry looms — many vertical including a Shannock.

The changing of the loom —a topics for future Gussets. Though maybe I talk about this a bit in Fringeless? Can’t remember. What I can say is that every time I think I know a thing or two about tapestry it surprises, delights and teaches me something new and there is room to play and explore beyond any boundaries I might once have imagined. Indeed, it almost seems that the simpler some parts get the more the others expand. How marvelous is that?

I credit much of this progression to the ideas and work of Susan Martin Maffei and Archie Brennan which never failed to catch my attention, from pipe and scaffold looms to four selvedge weaving, finger picking and weaving without a cartoon.

Leashes as contemporary shedding choice for enormous commissions— images at The Dovecot Studios, Australian Tapestry Workshop

Tommye Scanlin is an outstanding tapestry weaver, teacher and writer. Also a lovely lovely person. Here is her video on weaving with leashes and an open shed which explains it perfectly.

See Backstrap Dialogues for the whole story.

See Tucking The Tails for more on that.

I love etymology almost more than fiber and friends glaze over when I get all excited about the Greek words inside the English ones, and tend to run when I offer to write them.. My son now in his fifties, early developed a shutoff mechanism , yeah, mom, two Greek words, yeah..and Arabic, yeah..Latin in there, too..

Anyway you just illuminated, along with a marvelous demo about string heddles and why, the origin of WATERSHED!! Of course, of course. Also thank you.

Isn’t it annoying that the New York Times spelling bee puzzle will not accept “heddle” !